Accelerating the Global Low Carbon Transition

The core mission of Ioneer is to develop a U.S. based source of lithium and boron that can be produced in an environmentally and socially responsible manner, providing for two materials that are essential to achieve a sustainable future for our planet. Both lithium and boron are used in emerging clean technologies such as electric vehicles and storage for renewable energy and a diverse range of everyday items and innovative technologies that are essential to modern life. Sourcing both lithium and boron materials domestically is important to U.S. national security.

LITHIUM

Lithium is a critical raw material to enable technologies that reduce climate change. It is an irreplaceable component for current and next-generation batteries essential to the mass adoption of electric vehicles and electric battery storage systems that lead to greenhouse gas emission reductions.

- Essential to all types of EV batteries

- Conversion of green energy to base load power

- Strong demand growth predicted to beyond 2040

- Though the U.S. has the world’s 2nd largest vehicle fleet, there is very limited domestic lithium production

BORON

The future of clean technology both today and tomorrow will be defined by access to the critical minerals needed to enable these technologies. Ioneer’s Rhyolite Ridge Lithium-Boron Project will not only ensure that these resources are sourced in a sustainable and ethical manner but will also strengthen America’s position as an economic leader and reduce its reliance on foreign sources of boron.

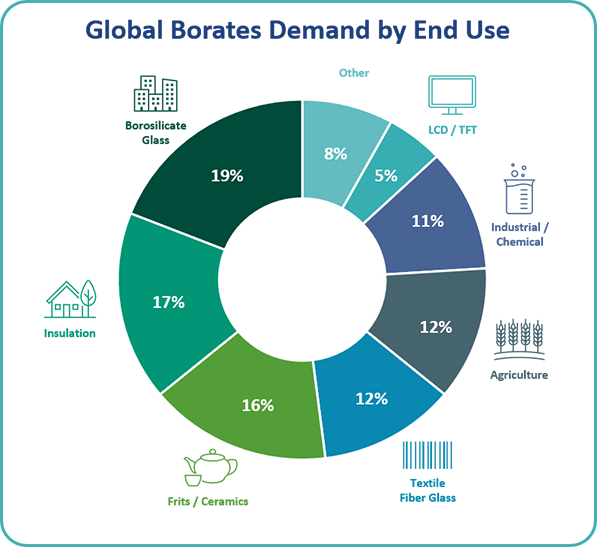

Boron is also a primary material for clean technologies and sustainability and is only produced in a few locations globally – 72% of world’s known reserves are in Turkey. It is used in over 300 applications, including home insulation, permanent magnets for electric cars and wind turbines, and advanced glass for televisions, computers, handheld devices and solar panels.

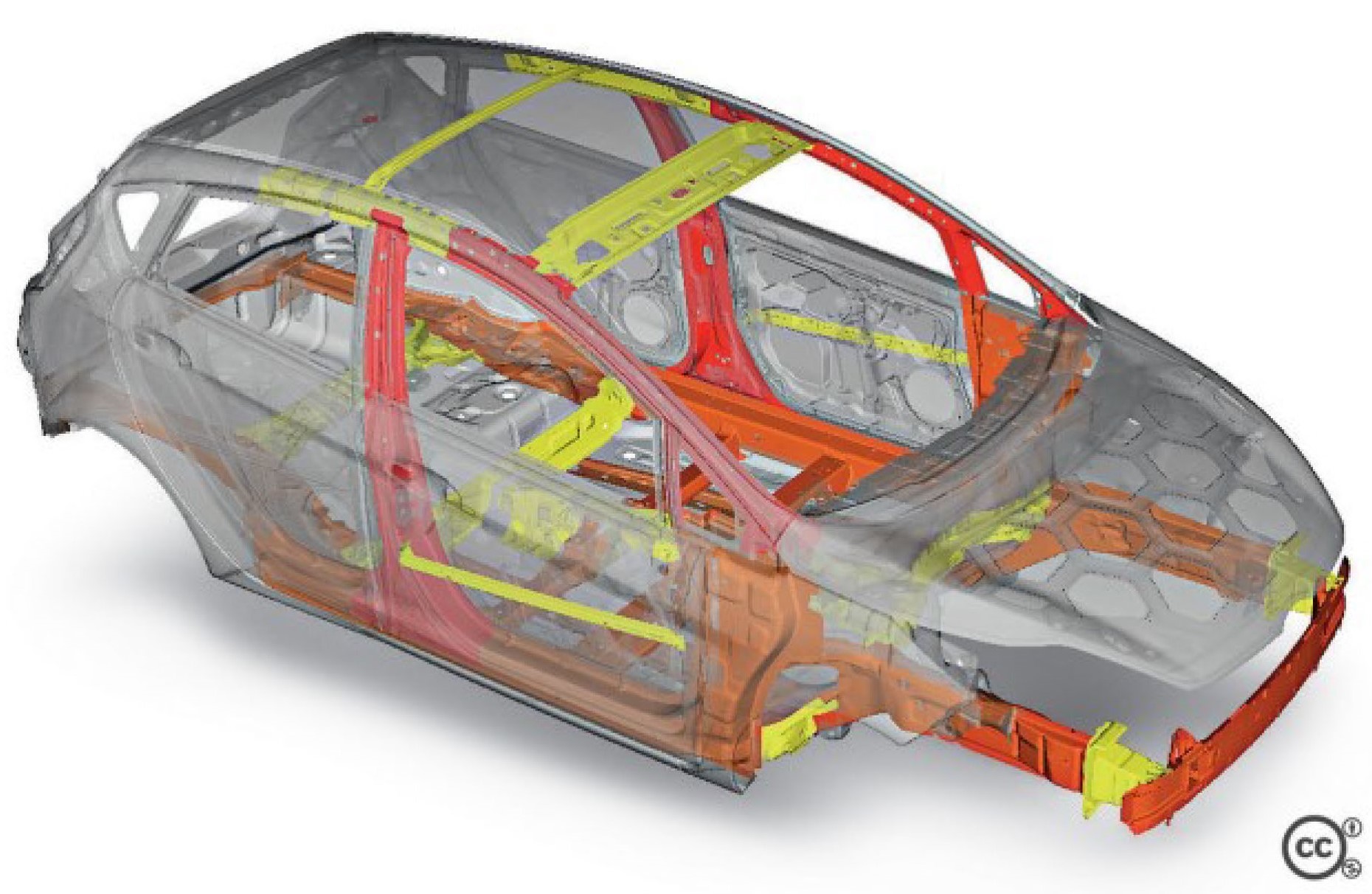

Uses of Boron in EVs:

- Permanent magnet motors

- Chassis for light weight strength

- Brakes

- Glass

- Batteries

- Airbags

Boron is also key to several climate technologies including:

- Hybrid and fully electric vehicles

- Insulation Materials that reduce energy use

- Wind turbine drive trains and blades

- Glass in Solar PV modules

- Hydrogen fuel cells

- Agriculture as a micronutrient supporting sustainable farming

A SUSTAINABLE AMERICAN FUTURE REQUIRES A STABLE SUPPLY CHAIN

The name Ioneer is derived from the combination of “ion” and “pioneer,” reflecting the Company’s aim to be pioneers in producing the materials for a sustainable future. The Rhyolite Ridge Project will also bolster American-led transition technology and responsibly produce the critical materials needed to reduce fossil fuel reliance.

In 2022, we announced that we have signed a binding offtake agreement with Ford Motor Company, and with

Prime Planet Energy & Solutions (a Toyota/Panasonic joint venture company) to supply lithium from Rhyolite Ridge for lithium-ion batteries planned for EVs built in America.

In May 2023, Ioneer signed an offtake agreement with Nevada based Dragonfly Energy which will allow for Nevada sourced lithium carbonate to be used in Nevada manufactured batteries.

Along with the increased offtake volume with EcoPro Innovation agreed upon in June 2021, we have now completed our pre-production lithium carbonate supply commitments.

ENABLING THE

SUSTAINABLE TRANSITION

The U.S. Government has increasingly emphasized the need for to promote electrification of the country’s transportation fleet as a way to reduce greenhouse gas emissions.

A domestic manufacturing supply chain, from raw materials to car production and ultimately through to recycling allows the U.S. to reach this goal while maintaining national security, creating high-quality jobs, promoting social justice, and ensuring compliance to rigorous environmental applicable regulations.

Electrification requires lithium.

Once federal permitting and construction is complete, Rhyolite Ridge is expected to quadruple current U.S. lithium chemical output. Ioneer will produce 22,000 tons of processed lithium materials per year and strengthen U.S. supply chains.

AMERICAN PRODUCTION OF

CRITICAL RESOURCES WILL PROPEL OUR

ECONOMIC FUTURE

The U.S. has long been a global leader of manufacturing and innovation. To build on that legacy, our country must have access to the base resources that enables transition technologies to flourish. Nevada has become home to an increasing number of lithium-ion battery companies over the last ten years. The Silver State now has a tremendous economic opportunity to create jobs across the supply chain – from raw materials to high-tech manufacturing, and in geographic areas both rural and urban.

As Nevada has become home to an increasing number of lithium-ion battery companies over the last ten years, the Silver State now has a tremendous economic opportunity to create jobs across the supply chain: from raw materials to high-tech manufacturing, and in geographic areas both rural and urban.

Ioneer has entered into formal memorandums of understanding with Nevada lithium battery manufacturers: Dragonfly Energy in Reno (the company behind Battle Born Batteries), Nextech Batteries in Carson City, and Lithion in Henderson. As production commences it is our desire that a portion of the lithium carbonate produced at Rhyolite Ridge will be utilized by these battery manufacturers and thereby creating a robust lithium supply chain right here in the Silver State.

DOMESTIC PRODUCTION OF CRITICAL RESOURCES PROTECTS PEOPLE & THE ENVIRONMENT

The global lithium market is expanding rapidly due to an increase in the use of lithium-ion batteries for electric vehicle and energy storage applications. Though the United States is home to several global lithium companies, it produces only 1% of the world’s total lithium.

By 2024, U.S. demand for lithium compounds used to produce lithium-ion batteries is estimated to be approximately 105,000 tons per year growing to over 300,000 tons per year by 2030 per year according to a Benchmark Materials Intelligence assessment of existing and planned production facilities. Rhyolite Ridge looks to produce over 20,000 tons per year of lithium compounds that can be used to manufacture batteries to power upward of 50 million electric vehicles over the site’s lifetime.

Large-scale borate resources are also very rare; Rhyolite Ridge is one of only two major lithium-boron deposits globally, and the existing two major suppliers of borates currently hold over 80% of the global market share.

Without the expansion of lithium and boron production, the U.S. would be forced to turn to foreign producers for these critical resources.

RIGOROUS REGULATIONS AND STRONG ENVIRONMENTAL PERMITTING

The United States has stringent regulatory requirements for water usage, waste disposal, and emissions. Ioneer’s chemical processing facility at Rhyolite Ridge will set a new industry standard for sustainable operations. In South America, where lithium is mined from brine formations the production process includes multiple, large holding ponds. Australian hard rock deposits require refining via roasting at high temperatures (1000°C).

Rhyolite Ridge’s unique mineralogy requires neither holding ponds nor roasting. Our production process is designed to limit water usage and minimize impact on the surrounding environment.

REDUCING GLOBAL GREENHOUSE GAS EMISSIONS WITH DOMESTIC INVESTMENTS

By sourcing domestic lithium for use in the U.S. electric vehicle supply chain, Ioneer’s environmental production footprint will be smaller. For example, current supply chains require transporting materials across oceans in fossil-fuel burning ships. Our processing facility will eliminate this need.

According to the U.S. Department of Energy, our project stands to reduce annual gasoline consumption by nearly 145 million gallons and prevent the release of 1.29 million tons of carbon dioxide each year. DOE’s projections relied on 2020 findings.

In April 2023, Ioneer released revised estimates which is expected to push those projected environmental benefits higher.

Operating Responsibly

The geology and mineralization of the Rhyolite Ridge Project is globally unique and affords the opportunity for Ioneer to extract strategic and critical minerals in an environmentally responsible manner.

Environmental stewardship is core to Ioneer’s mission. The development of the Rhyolite Ridge Lithium-Boron Project will produce large quantities of vital materials critical to reducing greenhouse gas emissions.

LOW EMISSIONS

Ioneer’s planned processing facility includes a sulfuric acid plant and related steam turbine, which will allow the Project to produce enough electricity to power its entire operations. This means zero reliance on the Nevada electrical grid and minimal use of fossil fuels to produce needed electricity. Our design, which is considered green co-generation, generates electricity that produces minimal carbon dioxide (CO2) emissions and minimal hazardous air pollutants.

REDUCED WATER NEEDS

Water use associated with Ioneer’s production of materials is extremely low compared to other lithium producers, especially compared to those that utilize brine extraction and solar evaporation. The design is optimized to reduce water demand and will recycle a majority of the water used in the refining process.

WILDLIFE & FLORA PROTECTION

One of the fourteen environmental baseline studies completed by Ioneer focused on characterizing the flora and fauna of the area. Amongst other species, this study concentrated on Tiehm’s buckwheat, a plant that is listed as an endangered species under the Endangered Species Act (ESA) . Ioneer fully supports the FWS’ decisions regarding the ongoing management and protection of Tiehm’s buckwheat populations, including an ESA listing. Information on our conservation efforts for Tiehm’s buckwheat is described in further detail below.

One of the fourteen environmental baseline studies completed by Ioneer focused on characterizing the flora and fauna of the area. Amongst other species, this study concentrated on Tiehm’s buckwheat, a plant that is listed as an endangered species under the Endangered Species Act (ESA). Ioneer fully supports the U.S. Fish and Wildlife Service’s (FWS) decisions regarding the ongoing management and protection of Tiehm’s buckwheat populations, including an ESA listing

MAINTAINING PUBLIC ACCESS

Ioneer is committed to being a good community steward. Ioneer continues to work closely with Esmeralda County to ensure that the access road is improved and maintained in a manner that preserves access for the public through and around the Project.

We carefully developed our Plan of Operations to allow for ongoing safe public access through the project area. Accordingly, Ioneer conducted an analysis of roads within the Project Area to ensure that we can safely retrieve and process the ore, while simultaneously ensuring safe public access.

PROTECTING VISUAL RESOURCES

A Visual Resources Technical Report was prepared in 2020 to characterize existing conditions associated with visual aspects in and around the Project Area. Ioneer is committed to minimizing the visual impact of activities and structures to viewers along publicly accessible roadways and public use areas. Dark sky lighting best practices will also minimize the effects of lighting on wildlife that may be present in the area, including bats.

Several examples of measures Ioneer intends to implement include:

- Careful placement and blending of stored materials to minimize contrast.

- Selection of building sites and new roads such that they would be hidden from view behind topographical features, where possible.

- Consultation with BLM on choice of colors of machinery, fencing, and powerlines; lighting design and color.

- Design, color, and surface texture treatments for the Processing Plant structures.

- To minimize the effects from lighting, Ioneer will utilize hooded stationary lights, where lighting will be directed onto the pertinent site only and away from adjacent areas not in use, with safety and proper lighting of the active work areas being a priority.

Protecting Tiehm’s Buckwheat

IONEER’S COMMITMENT TO PROTECTING TIEHM’S BUCKWHEAT AT RHYOLITE RIDGE

About Tiehm’s Buckwheat

Tiehm’s buckwheat (Eriogonum tiehmii) is a low-growing perennial herb, first identified in Esmeralda County, Nevada, in 1983. In December 2022, the U.S. Fish and Wildlife Service (FWS) listed Tiehm’s buckwheat under the Endangered Species Act and designated 910 acres of critical habitat to help conserve the plant.

To ensure the long-term viability of Tiehm’s buckwheat within and near Rhyolite Ridge, we have evaluated a broad range of protection and management measures to maintain and uplift the species. In developing these options, Ioneer consulted with experts who have studied other buckwheat species in Nevada, and who are familiar with similar conservation plans in the Western U.S.

Tiehm's buckwheat at Ioneer’s Conservation Center in May 2023

PROTECTING TIEHM’S BUCKWHEAT

Ioneer is committed to Tiehm’s buckwheat conservation while sustainably developing our Rhyolite Ridge Project, which will add a critical supply of lithium and boron to the U.S. electric vehicle supply chain and reduce greenhouse gas emissions.

Ioneer actively supported the U.S. Fish and Wildlife Services’ endangered species classification in December 2022. But prior to the federal designation, Ioneer had already invested $1.5 million in Tiehm’s buckwheat conservation. We have taken significant voluntary measures to ensure the plant and its habitat are protected, including installing fencing and signage around sensitive areas, conducting a full survey of the existing buckwheat population prior to any field activities, and developing and implementing a Bureau of Land Management (BLM)-approved protection plan. We have also constructed a dedicated greenhouse to grow Tiehm’s buckwheat and hired a full-time botanist, who is working to propagate and transplant seeds, a process called translocation, to Rhyolite Ridge. Once this is complete, Ioneer will tend to the plant’s continued recovery.

Ioneer has dedicated an additional $1 million annually for the plant’s continued protection. In May 2023, we opened a greenhouse dedicated solely to researching and conserving native Nevada species, and shared positive results in growing the plant in new soil conditions using from seeds safely collected from the known populations. We also hired two botanical experts to develop protection measures that will ensure the plant can thrive in natural conditions, including the extremes posed by climate change.

In developing these options, Ioneer consulted with experts who have studied other buckwheat species in Nevada, and who are familiar with similar conservation plans in the Western U.S.

Specifically, we worked in the following ways to protect and conserve this sensitive species in its natural habitat:

ESTABLISHING A PROTECTION PLAN

Ioneer has developed and implemented a BLM approved comprehensive Tiehm’s Buckwheat Protection Plan that includes strict measures that have been in place since Ioneer commenced exploration at Rhyolite Ridge in 2016. The goal of these voluntary measures is to ensure that the plant and its habitat are protected, and that the potential impacts caused by development of the Project are minimized.

A central component of the Buckwheat Protection Plan involves complete avoidance of all populations of Tiehm’s buckwheat, with a buffer zone between all mining activities and the plants. In the meantime, Ioneer is committed to increasing the area of the buckwheat population.

WORKING WITH REGULATORS

The protection and conservation of Tiehm’s buckwheat is a key component in Ioneer’s environmental stewardship and incorporated into all aspects of our planning and permitting activities.

In July 2022, the Company submitted to the U.S. Bureau of Land Management (BLM) a revised Plan of Operations that incorporated additional key commitments relating to buckwheat conservation:

- Minimizing and mitigating indirect impacts utilizing standard operating measures; and

- Minimizing disturbance within designated critical habitat.

Ioneer’s ongoing conservation efforts for Tiehm’s buckwheat are aimed at addressing current and future threats to the species, including climate-related threats.

Under the supervision of a full-time botanist, the Company is conducting scientific research to further increase knowledge of the species and is now operating a dedicated greenhouse in Nevada where plants are being successfully grown from seed collected from the known populations.

DEVELOPING A CONSERVATION PLAN

Ioneer is actively working with experts, regulators, and stakeholders to develop a comprehensive Tiehm’s buckwheat conservation plan that will be implemented during the length of mining operations.

Ioneer has budgeted $1 million over each of the next several years to conduct research and implement conservation measures to address existing risks to Tiehm’s buckwheat, and to uplift and expand the species.

In May 2023, Ioneer opened its dedicated greenhouse in Nevada to grow Tiehm’s buckwheat from seeds collected at Rhyolite Ridge.

In June 2022, we hired a full-time botanist who oversees the greenhouse and growing of the plant. Our greenhouse activities will help to guide and inform future propagation and transplant studies as we seek to support the Tiehm’s buckwheat population.

MINIMIZING POTENTIAL IMPACTS

Ioneer first instituted strict protective measures when we began exploration in 2016, prior to any field activities. We have conducted all work in consultation with regulatory authorities and guidelines and have taken great care to avoid the buckwheat subpopulations.

These efforts included modifying locations of boreholes to avoid the plants, drilling boreholes in several directions from a common drill pad to reduce the total amount of surface disturbance, educating employees and contractors about the plant, and other avoidance measures.

Ioneer will use Fugitive Dust Best Management Practices to ensure that there is no dust within any of the subpopulations.

As appropriate, additional targeted control efforts to limit the spread of invasive plant species and treat infestations will be employed utilizing best practices.

ENGAGING BUCKWHEAT SPECIALISTS

Ioneer has retained the services of academic and commercial experts to enhance our science-driven approach and develop protection measures that will ensure the plant thrives in its natural habitat. Our specialists are members of the Eriogonum Society, a professional association whose members have expertise in evaluating, propagating, and protecting various types of buckwheat.

Ioneer is working with The Conservation Fund to further explore viable options around protection and conservation efforts for Tiehm’s buckwheat. The Conservation Fund is one of the largest non-profit environmental groups in the United States and has worked with relevant federal agencies on buckwheat conservation strategies.

ENHANCING KNOWLEDGE WITH RESEARCH

Ioneer worked with researchers at the University of Nevada, Reno (UNR) over thirteen months to conduct a propagation and transplant trial for Tiehm’s buckwheat. The project successfully grew over 1,000 Tiehm’s buckwheat seedlings in the UNR greenhouse from seeds collected at Rhyolite Ridge. These seedlings were planted in three test sites in the Project Area in April 2020.

In January 2021, Ioneer announced key findings from a research report authored by UNR scientists. The report advanced knowledge of Tiehm’s buckwheat and created the foundation for future efforts to ensure long term protection in its natural habitat at Rhyolite Ridge.

Ioneer has expanded the scope of its work with commercial research partners alongside continued collaboration with academic researchers to determine the best ways to uplift the species.

COMMITTED TO TIEHM’S BUCKWHEAT CONSERVATION

Ioneer remains committed to pursuing conservation efforts for Buckwheat which address current gaps in our scientific knowledge of the species and to address threats that are unrelated to our proposed mining activities. We have completed numerous studies and greatly advanced scientific knowledge of the plant. This work has resulted in several new clarifications from previous studies.

Ioneer will continue its cooperative work with the relevant agencies on these efforts. Examples of the potential work developed with the BLM and the FWS include, but may not be limited to:

- Field surveys for new populations

- Seed collection and banking

- Herbivory monitoring

- Pollinator studies

- Seeding studies

- Ecological studies to understand the factors determining the distribution of buckwheat

- Propagation and transplant studies

- Demographic Monitoring

- Population modeling

- Climate monitoring

- Genetic analyses

Informed by the best available science, we are highly confident that with a combination of avoidance and mitigation efforts, we can achieve the successful coexistence of Tiehm’s buckwheat and our environmentally important project.

Advocating for a Sustainable Future

Ioneer supports policies at the state and federal level that will accelerate the growth of a Nevada based electric vehicle supply chain. Nevada has continued to show a bipartisan commitment to climate leadership by supporting the development and deployment of renewable energy resources and technologies.

Zero Emission Transportation Association

As a founding member of the Zero Emission Transportation Association (ZETA), Ioneer supports policies at the federal level that seeks to achieve 100% electric vehicle (EV) sales in the United States by 2030. ZETA is the first coalition of its kind in the U.S. that brings together industry leaders, advocates and non-governmental organizations across the transportation, clean energy, and technology sectors to drive policy changes that accelerate electric vehicle adoption.

One of ZETA’s key policy objectives is to advocate for domestic manufacturing across the EV supply chain, from critical minerals to vehicles. ZETA believes that as EV adoption continues to accelerate, federal policies ought to encourage domestic growth in manufacturing – creating jobs across the EV supply chain beginning with critical materials like the lithium and boron found at Rhyolite Ridge.

To learn more about ZETA visit zeta2030.org.

Clean Cars Nevada

In June 2020, the Clean Cars Nevada initiative was introduced and is directed to provide Nevadans with more choices for low and zero emission electric passenger cars and trucks through regulatory and legislative actions. Ioneer is a proud member of the Nevada Clean Cars Coalition – a group of Nevada businesses and organizations that have joined together to advocate for increased clean car standards.

On October 25, 2021, Nevada became the 16th state in the nation to adopt clean cars after the Legislative Commission approved the Clean Cars Nevada program in a bipartisan vote. The vote marked the final approval step after the Nevada State Environmental Commission voted unanimously to support the program in July.

U.S. Federal Initiatives to Increase Domestic Production of Critical Minerals

The U.S. Department of Interior has listed lithium as a critical mineral. Lithium is necessary to support technologies that will serve to combat climate change and reduce global carbon emissions, particularly those technologies associated with electric transportation and storage mediums that can convert intermittent solar and wind resources into baseload power.

Boron is considered a strategic mineral by the U.S. Department of Defense due to its use in defense applications including aircraft engine components, personnel and vehicle armor, magnets for electric motors, rocket fuels and wind turbines.

The U.S. Department of Commerce has developed a Federal Strategy to Ensure Secure and Reliable Supplies of Critical Minerals which includes a call to action to strengthen America’s critical mineral supply chains and defense industrial base.

IN NEVADA

Climate Change Action Plan

In December 2020, the State released a comprehensive climate change action plan to help curb emissions across Nevada. The first of these policies that is being considered by the state is to increase the availability of zero and low-emission vehicles in Nevada by requiring manufacturers to offer a minimum amount of ZEV and LEVs as a percentage of their overall fleet.

For the State to be successful in meeting its mandated greenhouse gas reduction targets and to fully realize benefits from the Electric Vehicle Demonstration Program and the Nevada Electric Highway initiative, lithium-ion batteries are essential for displacing the US fossil-fuel burning transportation fleet. A local electric battery supply chain is also essential for economic diversification and the creation of long-lasting, good paying jobs in rural areas.